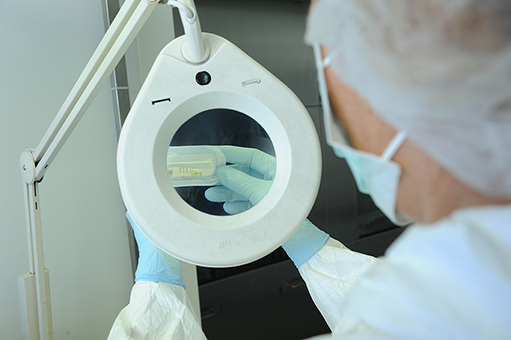

Packaging (Cleanroom Packaging)

DOT has clean rooms that are classified und according to accepted international standards. The following cleanrooms are available for the packaging of implants, their components and instruments:

- 5 class 7 cleanrooms (DIN EN ISO 14644/GMP class C)

- Total usable area approx. 400 m2 (including the locks)

- Regular hygiene monitoring (monitoring of ambient conditions and production water)

Our Range of Packaging Services

Sterile Packaging

Blister Packaging:

DOT has validated blister-sealing machines for sterile packaging under cleanroom conditions at her disposal. Products can be boxed and labelled in accordance with individual customer needs.

Pouch Packaging:

Our validated vacuum-sealing machines are especially designed for sterile packaging of medical devices under cleanroom conditions. The products are vacuum packed in PA and PE pouches. A protective gas can also be added if desired. The pouches can then be boxed and labelled as well. All sealing is subjected to a regular process monitoring.

Non sterile Packaging

Non sterile serial packaging:

The non sterile serial packaging covers the packaging of implants and instruments in PE pouches, including inline printing using any layout desired. Various counts of roll pouches can be packaged. These pouches can also be supplied perforated, thus allowing for easy separation (an ideal solution for packaging in sets).

Shrink wrapping:

Boxed products can be shrink-wrapped, with tear-open strips if desired.

Laminar flow packaging:

We also provide microbe-reduced packaging using a laminar flow box.

EN

EN  DE

DE