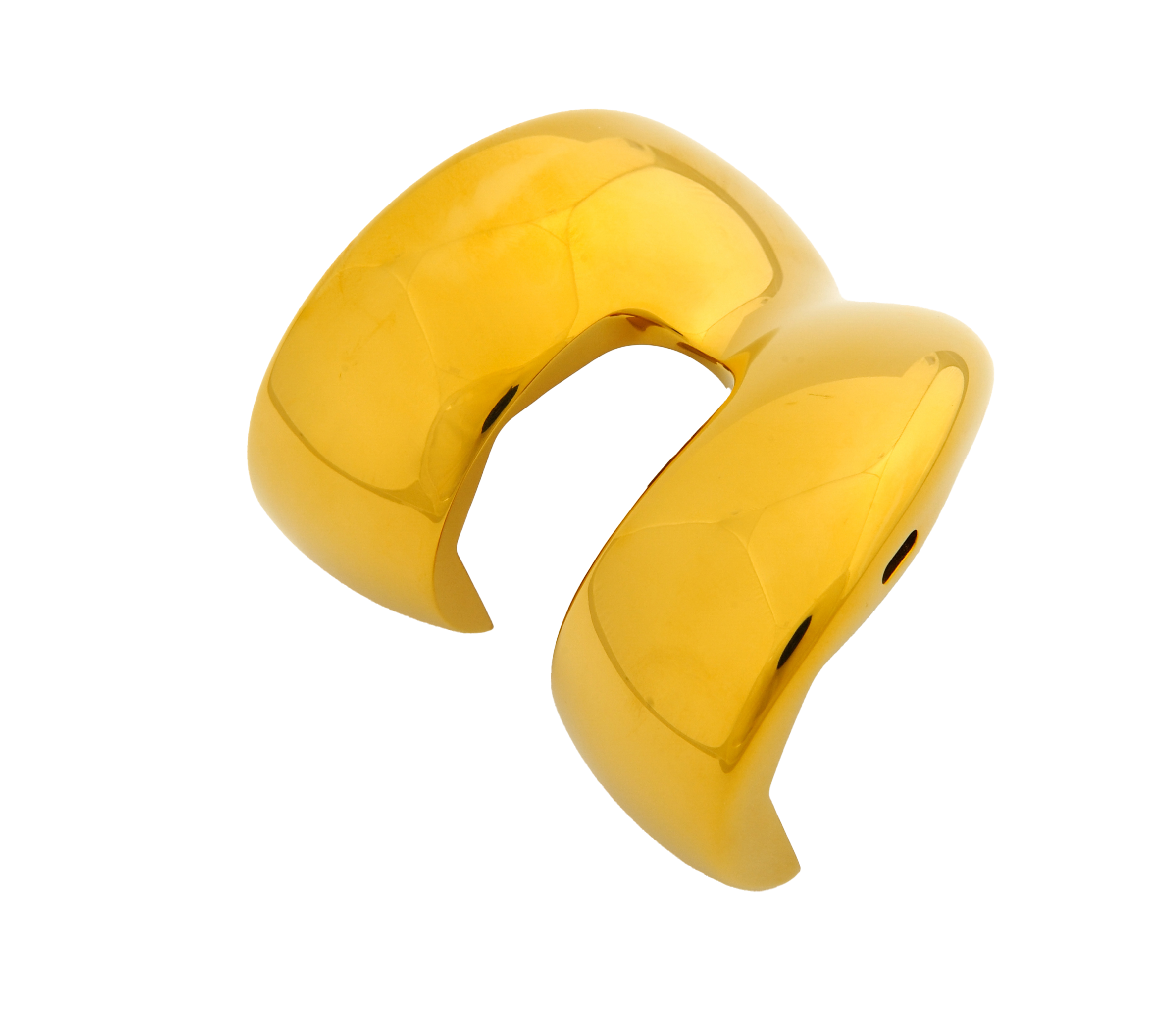

Titanium Nitride Coatings (TiN)

DOT video for TiN

Properties

- Coating thickness: 0,5-7 µm

- Adhesion strength: at least HF 1 (DIN EN ISO 26443)

- Coating hardness: ~2,300 HV

- Increased wear resistance and reduced abrasion

- Reduction of allergy potential

- Long-term chemical stability

EN

EN  DE

DE